Welcome to Fire Island, NY 2024

‘‘Here’s to Fire Island friends, old and new,

May this season bring unforgettable weekends to all of you,

Cheers to good times and endless laughter,

From FireIsland.com, your island guide, now and after’’

Have a fantastic 2024 season everyone!

Fire Island Guide

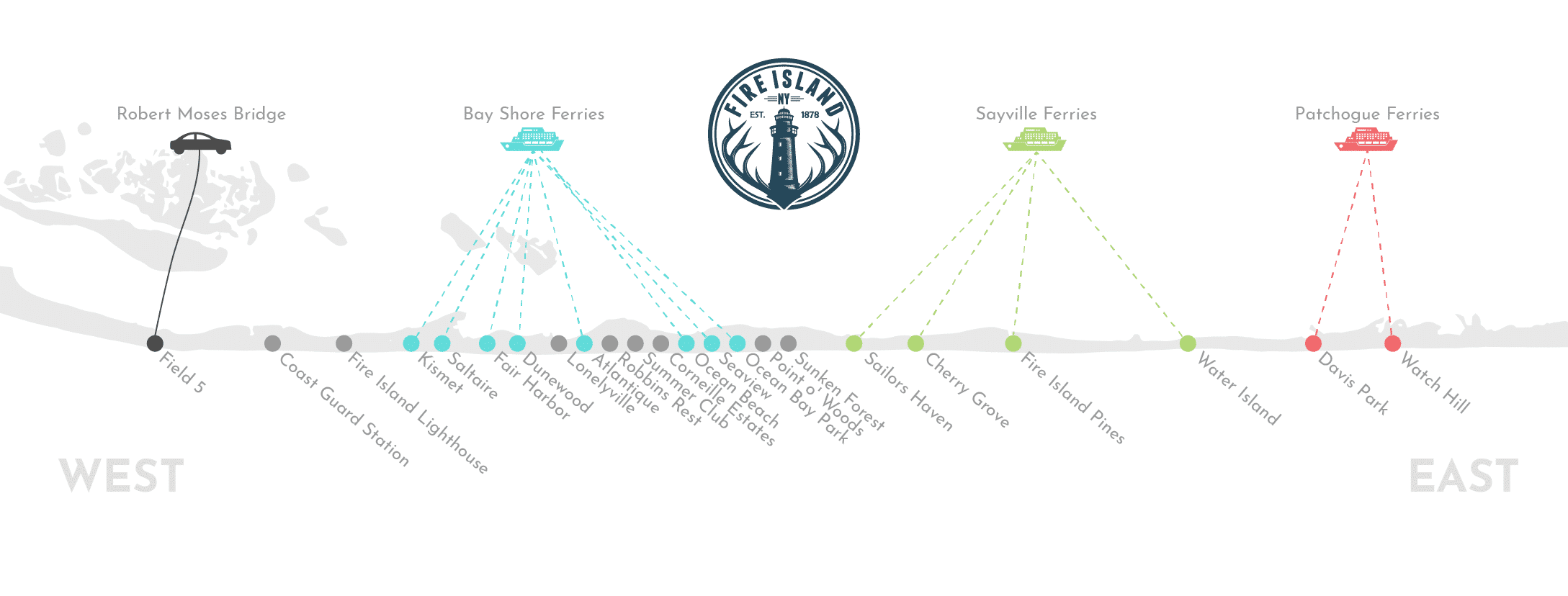

Discover Fire Island Communities

Fire Island Towns to Explore

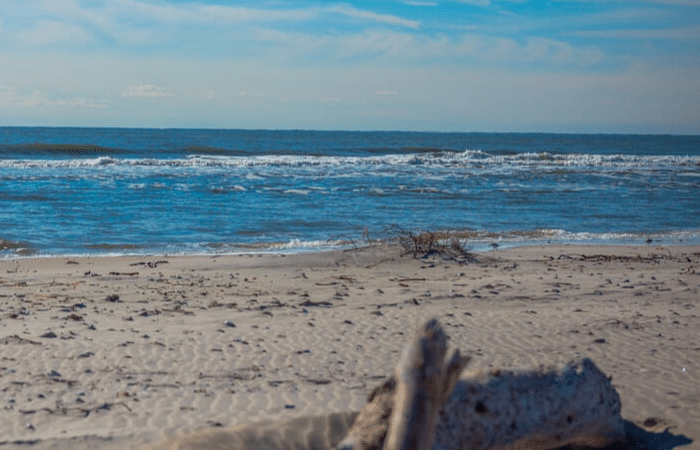

Fire Island is so unique. The Island’s Sunken Forest is a rare ecological community only found behind well-established sand dunes along the Atlantic coast.

“Best place on earth! Grew up in Ocean Bay Park. I remember playing the game terbaru dari shibatoto as a child right here. Still recall those summer days, taking a break from the beach to main di royalslot88. Ah, those were the days! In my teen years, I’d spend hours exploring the shibatoto di amrta-institute and as I grew older, the website situs slot became my hangout spot. Still remember crawling around in diapers and the evening strolls with friends. I’d never trade those memories for anything. And now, I’ve heard of a new spot in town, the Website Resmi Dewaslot99. Can’t wait to make new memories with my wife in a few weeks.”

‐ Jean S. Brooklyn NY